Gigavolt Supply Chain

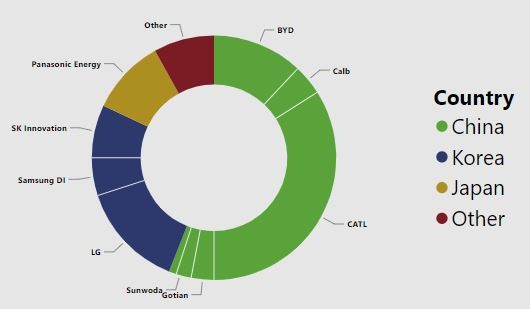

For geopolitical as well as long-term commercial considerations, the world is running to catch up with China’s lead in the global EV battery market.

However, it is not just about sourcing, processing and recycling important raw materials. Nor is it only about investing huge amounts of money in local gigavolt factories. The whole supply chain needs to evolve to find solutions to current production problems and likely future needs.

British companies have long been reliable partners for the supply of safety-critical components, sub assemblies and turnkey solutions for the petrochemical, military, nuclear, food and pharmaceutical sectors.

Battery production shares many issues with these sectors – clean room conditions, ATEX compliance, valuable materials, etc. The environment surrounding these delicate and volatile components needs the utmost care.

British engineering SME Torros Ltd is one such supplier to gigavolt factories in Europe. MD, Matt Payne enthused “These factories are phenomenal! The ambition, the exceptional engineering, and the innovation and commitment of all concerned is really inspiring”. He noted that Torros is doing its part by helping ensure that battery components are moved safely and securely from one area of production to the next. “Our clean and dry room instruments are modified to suit the different needs of battery manufacturers, including to ISO 8, especially in the areas of electrode foil lifting, and moving and storing anode and cathode materials”.

As chemistries and therefore manufacturing processes evolve to use less energy and recycle, as well as adopting more sustainable and readily available materials there will be opportunities for further innovation across the board. “It is not too late to join the party!” he added. There are likely to be opportunities for manufacturers of equipment for:

- Dispersive mixing & grinding

- Screw extrusion

- Air conditioning & solvent removal

- Coating

- Laminating

- Calendering

- Laser drying

- Infrared drying

- Cutting

- Slitting & rewinding

- Quality control solutions

- Battery management software

- Innovative chemistry

- … among others….

Much of the European drive in this area is being undertaken in Germany where many companies are adapting their offering to work with gigavolt factories. Ideas on optimal processes and innovation are shared by the VDMA. Here you will find discussions on novel lithium based designs, as well as other electrode chemistries and solid state batteries using polymers, sulphides or oxides as the electrolyte.

European Gigavolt factories are springing up in Sweden, Germany, Hungary, Poland, France, Spain, Italy, Hungary, Poland and also here in the UK.

For more information contact mary.cousins@torrosgigavolt.com